Asset Digitalization

Asset characterization is an important step in determining the process performance capability of a given unit operations equipment. As we saw in an earlier post, it forms the backbone of process understanding and science-driven development/transfer. Lets recap things a bit here:

- Asset characterization can be performed conveniently using computational/first-principles models.

- This results in a digital “nameplate” for the process asset under consideration, such as a crystallizer, a bioreactor, a tablet press or a granulator.

- Similar to a physical nameplate, the digital nameplate provides details on the capabilities of the asset or “process metrics” – in terms of expected mixing times, heat transfer capabilities, gas-liquid mass transfer effectiveness etc. – as a function of process conditions and material properties.

- Relationships between process conditions/parameters (PPs) and process metrics (PMs) capture the geometry or scale-dependent aspects of a given unit process or unit operation

When we consider only critical process parameters (CPP), critical material attributes (CMAs) and a critical set of process metrics (CPM) to characterize the performance capabilities of a process asset, we are in a position to draw on the quality-by-design (QbD) paradigm also.

It is typical for complex processes to have a few different CPMs, each of which characterizes one or more physical phenomena or process capabilities. The relationship between CPPs, CMAs and CPMs – as we will see below – is captured in a “Digital Nameplate” things get done right first time, every time! of the asset, which we dub its DNA.

Just as the DNA of a living organism holds all the information relevant to a living organism’s being, the DNA of the asset holds all the information relevant to its performance capabilities with respect to a specific unit operation.

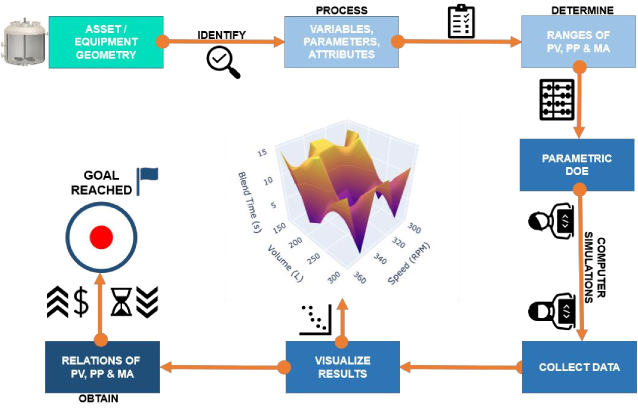

For any given process asset, PP-PM relationships can be obtained effectively using “asset digitalization”. The digitalization of a process asset is performed using the following steps:

- Identify PPs, MAs and PMs relevant to the asset: This step usually involves utilizing prior knowledge accumulated about the process and the asset. For the unit operation under consideration, a fairly comprehensive list of PMs must be drawn taking all physical processes into account.

- Determine ranges of values for PPs and MAs: Determine the likely range of process and material conditions that the asset is likely to encounter.

- Develop PP-PM relationships for the relevant ranges : Use a combination of DoE, computational modeling and reduce-order model (ROM) generation to obtain the PP-PM relationships for the asset.

- Store asset DNA information for later retrieval: SimSight stores the PP-PM relationships in an object-oriented database of assets.

Once the DNA of an asset is created, it is ready to be used for a number of purposes.